State-of-the-art industrial air purifier filters

Our industrial air purifier filters can capture air pollution of any shape or size. With our customizable industrial air filters, you can bring fresh air to your business, no matter your industry.

Our industrial air purifier filters can capture air pollution of any shape or size. With our customizable industrial air filters, you can bring fresh air to your business, no matter your industry.

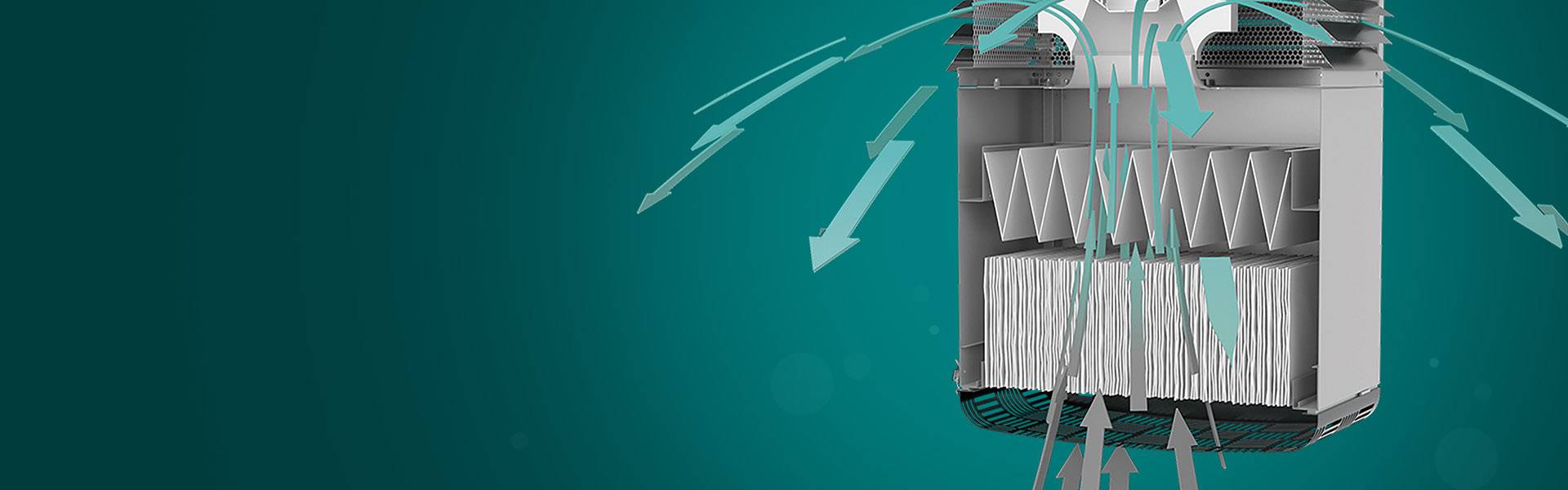

Industrial air purifier filters: An overview

Air purifier filters are the core of industrial air cleaners, and they play a vital role in removing harmful particles including dust, vapor, gasses, smoke, or other microorganisms. However, there are different types of industrial air filters, and they each serve a different purpose.

The right industrial air filter for your business will depend on your industry, the environment at your workplace, and the amount and type of particles in the air. The highest-performing filter for your needs will have a specific dust absorption capacity and permeability, based on the particles most common in your building.

The different types of filters for air purifiers

Zehnder’s air cleaning solutions offer many different kinds of filter configurations, tailored to fit specific environments. The most important are flimmer filters (a Zehnder inhouse development), pocket filters, and compact or HEPA filters.

Flimmer filters:

Flimmer filters are a popular choice, because they can capture a lot of dust while still allowing a high air-flow rate. These unique filters can be used on their own, or you can pair them with a pocket or compact filter.

Zehnder's FlimmerM®, which is only available through us, offers an extra benefit: When combining flimmer filters as a pre-filter for a compact or pocket filter, you will significantly extend the life of the second filter!

Flimmer filters:

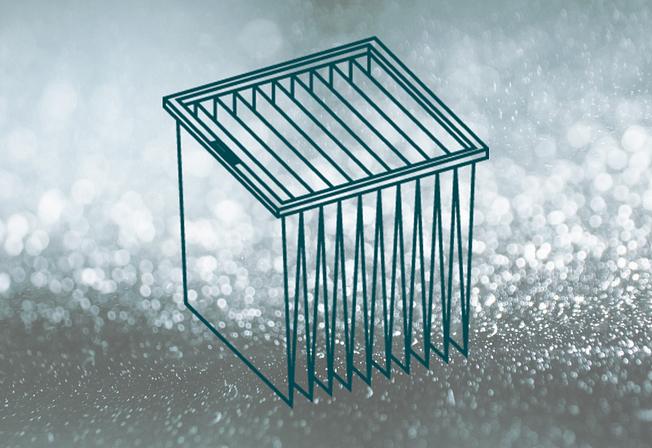

Pocket filters:

Pocket filters:

If you want an industrial air filter that can take on very high levels of dust, pocket filters (or bag filters), are just what you need.

These get their name because they are made up of several pockets arranged in a row. As air passes through, the pockets capture harmful particles, releasing clean air on the other side.

Our pocket filters can be used on their own or as pre-filters or downstream filters, meaning you pair them with other filters for air purifiers to achieve maximum protection.

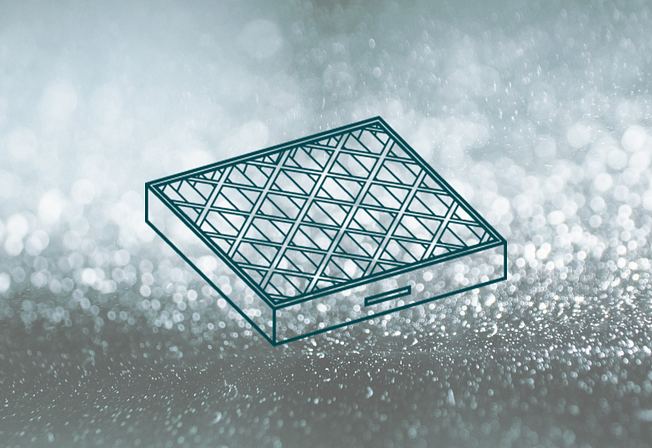

Compact filters and HEPA filters:

There are many different classes of compact filters, from coarse filters that trap larger particles, all the way down to HEPA filters, which can clean the air of harmful ultrafine particles, including chemical, biological, or even radioactive particles.

These filters are used as supportive filters, and we can install different filter classes based on your needs, up to HEPA 14.

Compact filters and HEPA filters:

Often, multi-stage filters are the best choice

While many of our air purifier filters function well on their own, multi-stage industrial air filters offer several benefits. Combining filters can help you remove more and varied types of particles while maintaining high air flow rates. On top of that, they have a longer service life, are more adaptable, and can help you save on energy bills.

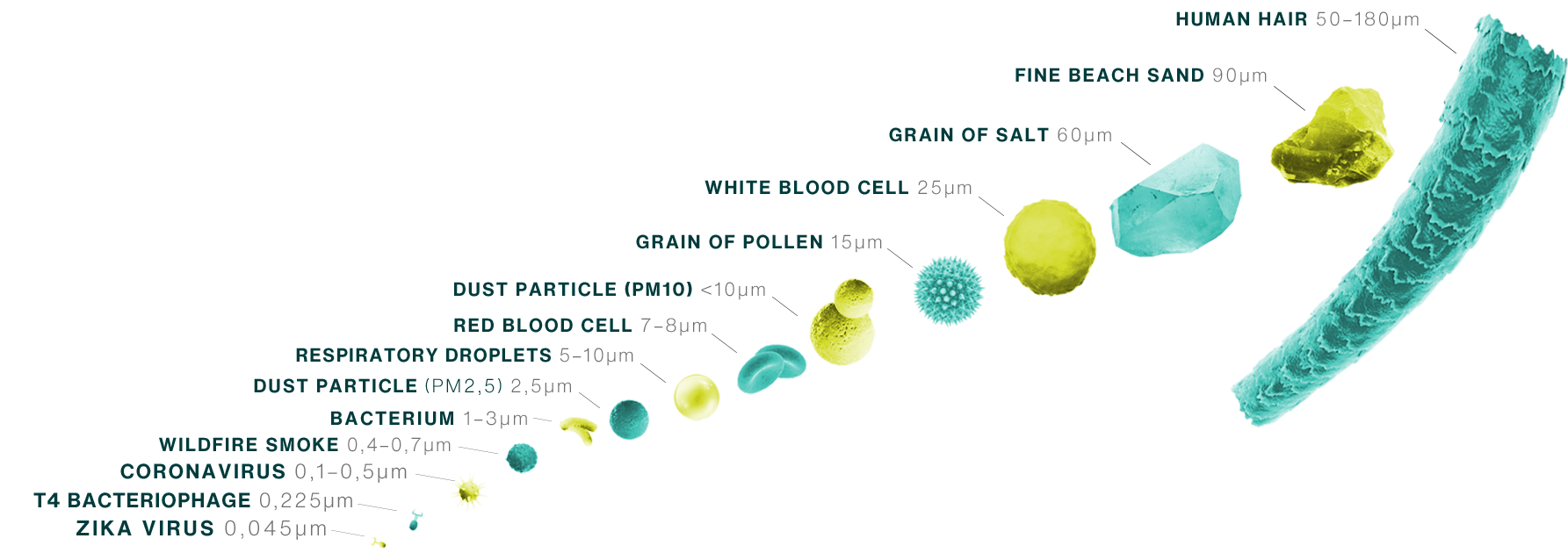

It's all down to particle size: Important facts about filter classes

"Filter classes" might not be a familiar term, but don't worry – we can clear it up for you.

There are different classes of filters, defined and regulated by various organizations, like the EN or ISO. Classes are assigned based on how well the different filters remove harmful particles of all sizes from the air. Filters with a higher class are more effective at removing harmful particles.

Filter classes are written as PM, which stands for particulate matter. The different levels of PM indicate the size of particles that filter can remove from the air. For example, an ISO ePM10 80 % class filter can filter 80 % of all PM10 particles.

- PM1: Particles smaller than 0.001 mm

- PM2,5: Particles between 0.001 mm and 0.0025 mm

- PM10: Particles between 0.0025 mm and 0.01 mm

- Coarse dust: Particles equal to or larger than 0.01 mm

Understanding air purifier filter standards

ASHRAE 52.2 and ISO 16890

In the United States, the ASHRAE 52.2 is the primary standard used to test air filters. Internationally, the ISO 16890, which replaced the previous EN779:2012 standard, is the primary standard. The ISO standard requires filters to capture at least 50% of particles from a given fine dust category (PM).

EN1822

EN1822 regulates the filter classes for very fine filters (particles ≤ PM1). It is the valid standard for the certification of EPA, HEPA, and ULPA filters in both the United States and Europe.

How to find the best filter for your business

It can be hard to know exactly which type of filter or filter combination will be the best fit for your business. After all, each industrial air filter is designed for specific environments and air particles.

Fortunately, you don't have to make the decision alone. Zehnder's air quality experts are ready to help you find exactly the right air filter for your unique business, whether you need an air purifier with HEPA filters, or filters that can take on grit and oil mist.

Are you ready to clear the air at your business? Get int ouch with us today, and we'll help you take the first step toward clean, healthy air.

How to find the best filter for your business

Let's clear the air

Your team breathes this air every day. Let’s make it better. We’re here to answer your questions and support your needs. We’d be delighted to advise you on your air purification requirements. We take your air as seriously as we take our own.