Respirable crystalline silica (RCS) is an extremely fine particle produced by cutting, drilling, or otherwise breaking common materials. It is a serious hazard in the workplace, and inhalation can cause silicosis and lung cancer.

There is no safe level of silica dust that a worker can inhale, meaning that even companies that are legally compliant may still be exposing their employees to dangerous levels of silica.

Some common sources of silica are:

Multiple studies conducted in the US and around the world have proven the link between silica dust and various types of cancer.

Approximately 2 million workers in the US are at risk of silica inhalation, according to the National Institutes of Health.

OSHA estimates that 12,173 iron foundry workers in the US are exposed to RCS over the new permissible exposure limit.

The CDC estimates that between 1999 and 2013, a total of 2,065 deaths listed silicosis as the underlying cause.

Breathing in silica dust can cause lung cancer, silicosis, and COPD.

It takes under a year of working with silica to develop silicosis. There is no cure for this deadly disease.

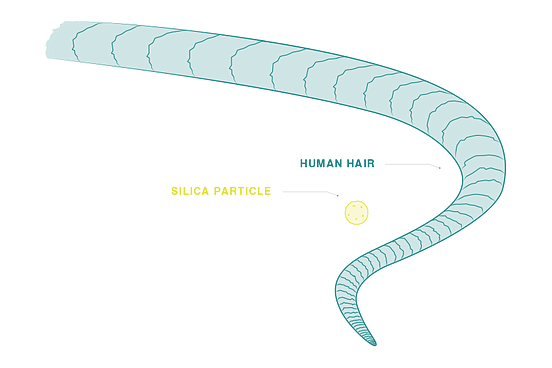

Harmful silica particles are 1/1000th smaller than the diameter of a human hair!

As a result of their tiny size – the same reason they can do so much damage to your employees‘ lungs – silica particles remain airborne for an incredibly long time.

Even the air currents generated by someone walking by is enough to disturb silica dust, and once it’s in the air, it can take up to four hours to settle again. During this time, it poses a considerable health risk, as even a small amount of respirable silica dust can be hazardous.

It can be incredibly costly for businesses to remain compliant with the OSHA silica standard as they increase cleaning efforts and install expensive extraction systems. This is particularly true as regulators lower silica dust exposure limits, putting pressure on employers to invest more in these systems.

In the USA, it is expected that compliance could cost employers up to $1 billion a year. However, these systems often aren’t even effective enough. Pick a solution that actually works by choosing Zehnder, the air cleaning experts.