Avoid contamination and comply with regulations

Avoid contamination and comply with regulations

Production facilities and warehouses are bustling with activity. Spores, germs and bacteria are constantly introduced into the facility, multiplying rapidly, no matter how careful your employees are. Meanwhile, ingredients such as flour and oil are thrown into the air during production, while grinding grain produces extremely fine particles. They contaminate the working environment, and dust accumulates – including in areas involved with shipping and receiving.

For beverage companies, dust can settle on bottles and cans in storage areas. Stopping this torrent of airborne particles is no easy task, but it’s one you must shoulder.

Even minuscule amounts of pollutants are dangerous for consumers and employees, potentially making them sick. In the food industry, reputational loss could easily turn into a disastrous public scandal. Failure to keep up with government regulations therefore poses a serious business risk: perception of your company may be damaged, perhaps irreparably so. Your business will fail audits, receive fines, and could even be shut down. HACCP compliance will shield you from these catastrophes.

HACCP stands for Hazard Analysis and Critical Control Points. It is an international standard internal monitoring system for food companies intended to ensure the health and safety of employees and consumers.

Beyond simply catering to the tastes of the market and ensuring your products are of a high standard, it’s also your responsibility to make sure that your workers and the public are safe. HACCP food hygiene regulations are excellent guidelines for doing so.

Complying with HACCP principles also shows the world how seriously you take your quality standards and your responsibility to your consumers and employees, all contributing to a better corporate image and a greater chance of success.

Food production is one of the dustiest industries. One in five decision-makers in food and beverage acknowledge that their facilities don’t address dust adequately.

Non-compliance poses a serious risk to businesses of all sizes. In 2016, the HSE fined a bakery company in the UK £36,000 for failing to meet standards.

In 2019, the US Food Safety and Inspection Service (FSIS) conducted severe additional inspections. They refused entry to 5 million lb of meat and poultry, and 5,000 lb of eggs.

From 2014 to 2018, the most common factor in occupational asthma cases across the UK was exposure to flour.

In the food and beverage industry, contamination can occur through the whole production process, not just during processing. Potential contaminants include natural toxins, metals and other inorganic materials, and pollutants.

The WHO has found that prolonged exposure to unclean indoor air can cause acute respiratory syndrome. They have also linked particulate matter in the air with reduced productivity.

Industry bodies and regulators around the world try to emphasize the importance of clean air in the workplace.

The problem is that many people still believe that outdoor air pollution can be escaped simply by going indoors.

However, indoor air quality can be just as bad, and even a lot worse, than it is outside.

To meet HACCP food hygiene regulations, you need clean, pathogen-free air. Poor indoor air quality poses a significant risk to food products, employee health, as well as to machinery and installations. Dust and other airborne pollutants buildup can harm the efficiency and significantly shorten the lifespan of your equipment and machinery, potentially grinding the whole line to a halt. In short, allowing pollutants to build up in your business is not an option.

However, keeping a facility clean and free from airborne particles can be incredibly time-consuming, costly and resource-intensive. It also keeps employees away from their main focus: making a high-quality product. Fortunately, there are tools and options for businesses to produce clean air quickly, easily, and cost-effectively.

To establish an effective HACCP compliance plan, you need the right tools and methods – and that’s where we can help.

Convential methods like LEV are not enough. For full HACCP compliance you must capture pollutants at the source. Air cleaning systems by Zehnder can help you exactly do that.

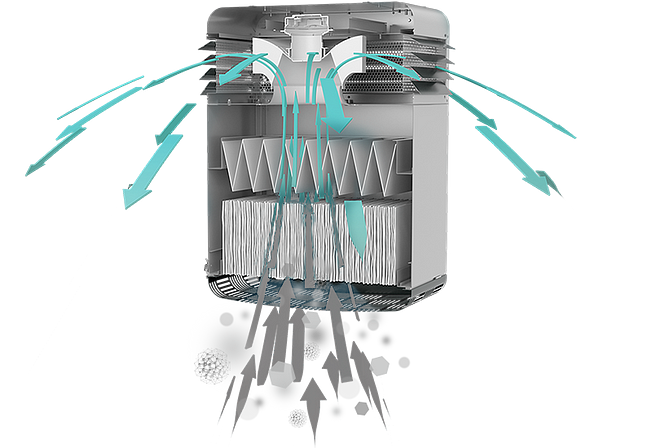

Standard dust collectors seek to accumulate high volumes of dust, mostly by using bag filters. However, these filters are incapable of capturing the tiniest micro-organisms. Zehnder’s solution is a patented dual stage filtration system called FlimmerM®.