Air purifier filters are at the heart of every industrial air cleaner and are largely responsible for removing dirt particles such as dust, gases, vapours, smoke, and microorganisms from the air in your building. But not all filters are the same.

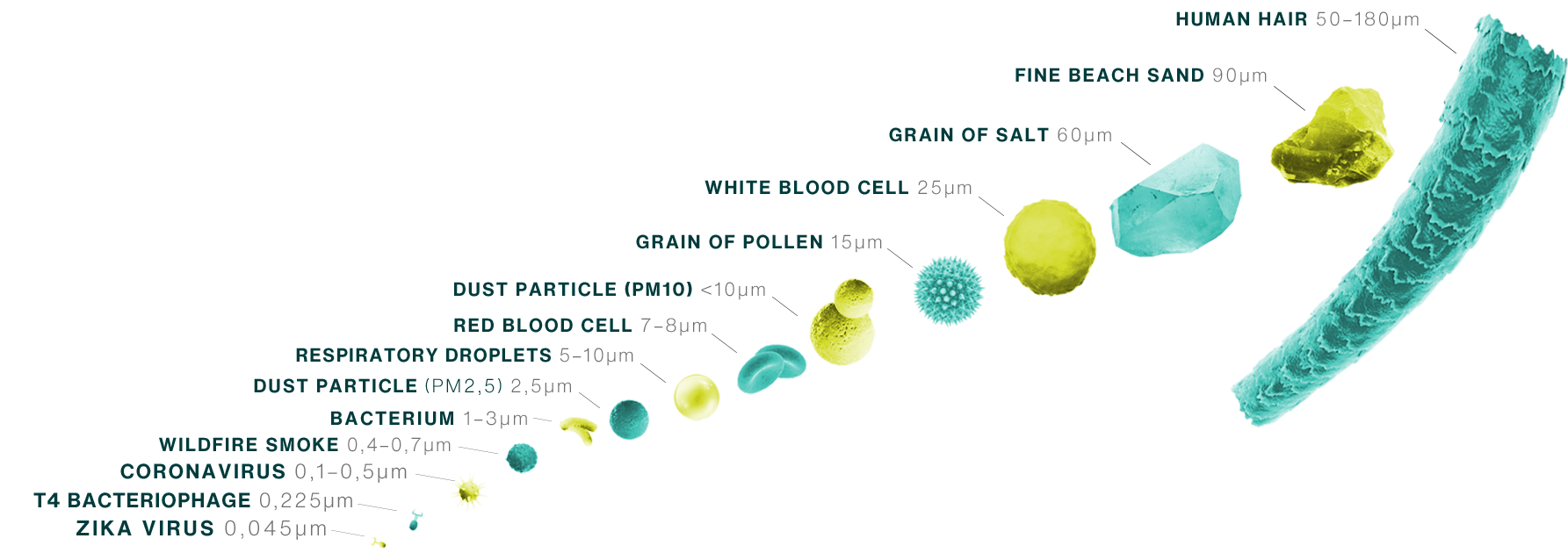

There are a variety of different filters that are highly effective, depending on the environment, the industry, and the amount of particles in the air. To choose the right filters for your needs, it is important to understand the particles you are dealing with. This way, your air purifiers are equipped with the ideal mixture of dust absorption, capacity, and permeability.

Zehnder’s air cleaning solutions offer many different kinds of filter configurations, tailored to fit specific environments. The most important are flimmer filters (a Zehnder inhouse development), pocket filters, and compact or HEPA filters.

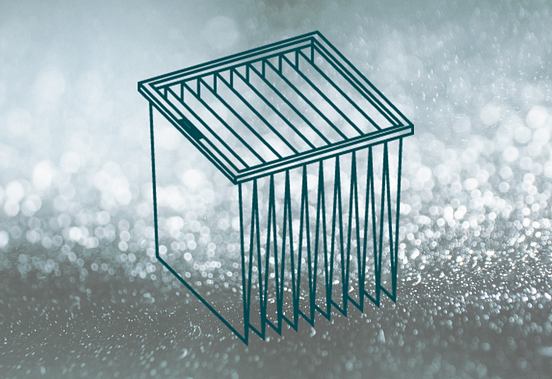

Flimmer filters are made from thousands of polypropylene fibers that electrostatically trap particles. Compared to other air purifier filters, flimmer filters allow a high air flow rate – even if they contain a lot of dust. They can be used alone or in combination with a pocket or compact filter.

Patented Bonus: When flimmer filters are used as a pre-filter for a compact or pocket filter, you can significantly extend the life of the secondary filter! This extra is only available from us and is patented as FlimmerM®.

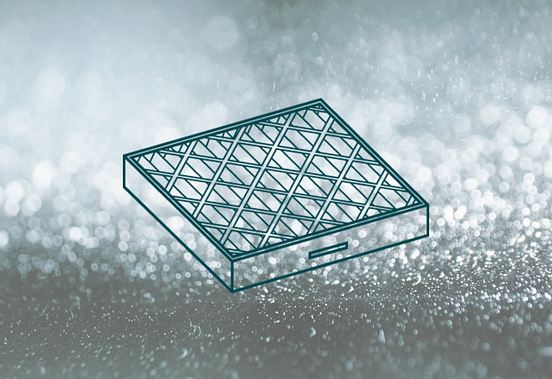

Pocket filters (also known as bag filters) have it all – because they deal with very high levels of dust.

They are called pocket filters because the filter is made up of several adjacent pockets. The air, including disruptive particles, is drawn into these pockets, and released again on the other side, cleaned.

Pocket filters can be used individually or in combination with other filters (as pre-filters or downstream filters).

Compact filters come in many different filter classes, ranging from coarse filters for trapping larger, coarse particles, to what’s known as HEPA filters for harmful ultrafine particles, whether chemical, biological, or even radioactive.

They work as supportive air purifier filters and can be obtained in different filter classes (up to HEPA 14).

This is because multi-stage filter solutions are more effective in terms of the amount and type of particles they can remove, have a longer service life, are adaptable, energy efficient, and can handle higher air flow rates.

Filter Classes – another word that can cause confusion. Here we'll shed some light onto this:

Firstly, there are different filter classes that have been defined and standardised by different organisations, for example the EN or ISO classifications. These classes indicate how efficiently various air filters remove harmful particles of all sizes from the air in the room. The higher the filter class, the more effective the filter is at removing particles from the air.

The most important distinguishing feature is always the size of the particles to be filtered. This is given in PM (particulate matter). For example, an ISO ePM10 80 % class filter can filter 80 % of all PM10 particles.

ISO 16890 and ASHRAE 52.2

This is the internationally recognised classification and testing standard for air purifier filters. It replaces the previous EN779:2012 standard. To comply with the ISO 16890 standard, an air purifier filter must be able to filter at least 50% of the particles from a certain fine dust category (PM). The ASHRAE 52.2 standard is primarily used in the United States

EN1822

EN1822 defines the filter classes for very fine filters (particles ≤ PM1). It is the valid standard for the certification of EPA, HEPA, and ULPA filters in Europe and the USA.